Despite what many people think, insulating your home or office doesn’t have to be long and tedious. There are many insulation products readily available. Most of them are cheap, and you can install them on walls, floors, and roofs, even on your own.

If you’re after lower energy bills, a comfier home, and a higher EPC rating, then insulation boards are a cost-effective way to get that done. There are several types, but all have a decent thermal efficiency that retains warmth during the colder months and keeps heat out in the summer. And they’re good against moisture, so they prevent mould and mildew and can act as an acoustic barrier, which is ideal if you live in a busy area.

Why Use PIR Insulation Boards?

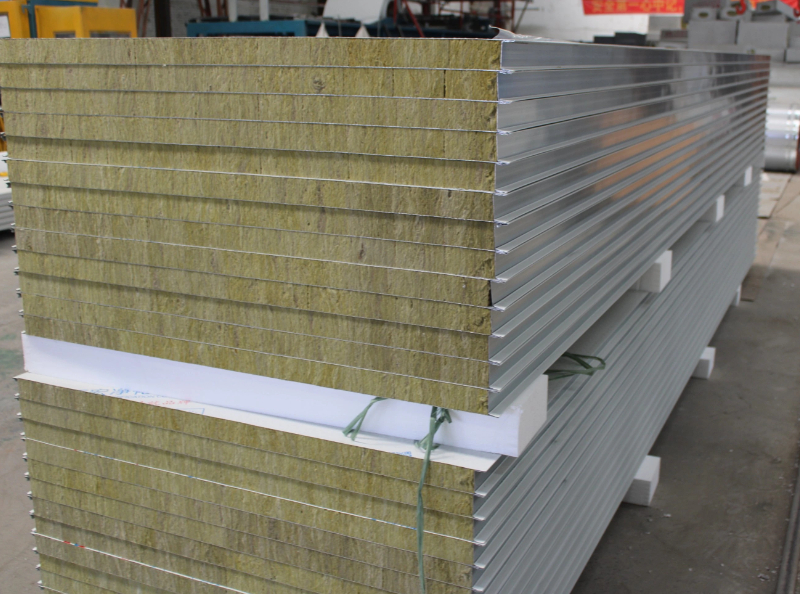

PIR, or polyisocyanurate boards, are popular due to their high thermal efficiency, low cost, and simple and quick installation. They also outperform comparable rigid foam boards in other key areas, particularly fire resistance, durability, and eco-friendliness. And they’re produced in varying thicknesses, so finding a board that fits won’t be an issue, as is common with other insulation boards.

Many of the favourable properties are due to how these boards are made. They are essentially thermoset plastics, produced by liquid polyols and MDI (methylene diphenyl diisocyanate) in the presence of blowing agents and additives. The resultant foam is cooled and shaped into boards of the desired thickness.

The higher concentration of MDI, compared to similar polyurethane (PUR) boards, leads to a denser, closed-cell structure that is also more durable, in addition to having a much better tolerance to heat and flames. PIR insulation boards have some of the highest fire ratings of any insulation material.

Moreover, they won’t deform or shrink over time, have very high compressive strength, and aren’t susceptible to vermin or adverse weather conditions. In a word, they outperform many competitive boards without actually costing more.

Where They’re Used

PIR boards are also versatile and have virtually replaced their PUR siblings as the industry standard. Today, they are found in floors, roofing applications, and different types of walls.

Insulating Floors

The high impact resistance and compressive strength make these boards ideal for insulating all types of floors. Solid concrete or stone floors are prime candidates, as are suspended timber floors.

The first can have PIR insulation boards installed either below the floor, a common practise in newer homes, or above the floor in older houses. Here, the boards are usually placed under a layer of concrete screed and OSB board, or used without screed in floating floors.

Suspended timber boards can also benefit from rigid foam insulation, either above or below the joists. One benefit is that thinner boards, such as 80mm PIR insulation, can be used instead of spray foam, mineral wool, or fibreglass batts. These should be at least 150mm thick to have the same thermal efficiency. This means they may affect the recommended ceiling heights approved by British Building Standards.

Roofing

The insulation used in roofing applications helps rising heat remain inside, with boards acting as heat barriers. PIR boards are effective in both flat and pitched roofs, mainly due to their moisture resistance when used with metallic fascias.

Usually, this is in so-called cold roofs, with the boards placed under the rafters. Newer builds have boards installed above the rafters with the roof covering removed and a breathable membrane placed on top. This is on more thermally efficient “warm” roofs.

Additionally, the PIR core can be bonded to plasterboard where there’s a need for added rigidity and is a good alternative to glass and mineral wool when insulating lofts and ceilings.

Walls

These boards perform best on walls, which account for over a third of total heat loss. With its exceptional ability to retain heat, PIR is very efficient in both cavity and solid walls, when lining external masonry walls (in combination with moisture-resistant phenolic panels) and placed behind polymer renders or dry cladding.

In internal wall insulation, the boards are often attached to insulated plasterboard or plywood. For cavity wall applications, these boards are used for insulated sheathing on timber and steel frames, as well as insulation between studs on timber frame walls.

Choosing the Right Thickness

An insulation material’s ability to resist heat is given as a fixed measurement, or total R-value, and besides the properties of the material, is also dependent on thickness.

For instance, 25mm of solid wood has an R-value of 1, mineral wool in the same thickness has a value of 4, Extruded Polystyrene (XPS) at 4.7, PUR boards at 6, and PIR boards 7. Of course, the higher the number, the more efficient the material is. That said, an 80mm PIR insulation board will have the same thermal efficiency as a 120mm XPS board.

This is important for two reasons. First, PIR boards can be much thinner and still retain as much heat as thicker insulation materials. This is critical in areas with limited space, such as flooring applications and cavity walls. The other reason is that where space isn’t an issue, there’s nothing that can quite rival PIR for total efficiency. You’ll be seeing considerably lower heating and cooling bills when choosing PIR.

Boards are produced in 25, 40, 50, 60, 75, 80, 90, 100, 120, and 150mm variants. And they come in the standard building sizes of 1200 by 2400mm for most jobs, and 1200 mm by 1200mm or 1200mm by 600mm for specific uses like flat roofs. What’s of note, is that boards of variable thickness can be used side by side without the risk of drafts or thermal loss.

Other Considerations

To achieve those high R-values, virtually all PIR boards have aluminium facer foils. This acts as the first line of defence against moisture and vapour and works extremely well to resist the buildup of mould or mildew. It also reflects heat and prevents the spread of flames and toxic fumes to other structural elements.

The boards are very lightweight. A standard 80mm thick 2400 by 1200mm board comes in at just under 8 kilos, so is easy to handle and transport, and even easier to install. This can be a moderate DIY project that many people can do themselves and requires basic tools. Although PIR is non-toxic and a much safer option than mineral wool or fibreglass, use PPE gear such as face masks and goggles during installation.

Lastly, consider brands and pricing. As mentioned, PIR boards can be much thinner, and in insulation, this means lower costs. The prevalence of these boards in recent years has led to lower prices in general, making other insulation boards hard to justify. Moreover, customers can choose from half a dozen brands, with most headquartered in the UK. They have detailed product lines, so no matter which part of the house needs insulating, there’s a PIR board for every job.