When it comes to choosing the right materials for various applications, understanding the differences between options is crucial. In the realm of packaging, signage, and displays, two commonly used materials are foam and Foamex. While they might sound similar, they possess distinctive qualities that make them suitable for specific purposes. In this article, we will delve into the dissimilarities between foam and Foamex, shedding light on their unique properties and applications. So, if you’ve ever wondered which material is best suited for your project, read on to find out more.

What is Foam?

Foam, as the name suggests, refers to a lightweight and versatile material composed of small air bubbles trapped within a solid structure. It is created by mixing a liquid chemical compound with air and a foaming agent, which expands and solidifies into a cellular structure. Foam offers excellent cushioning and shock absorption properties, making it ideal for protective packaging, mattress production, and upholstery applications.

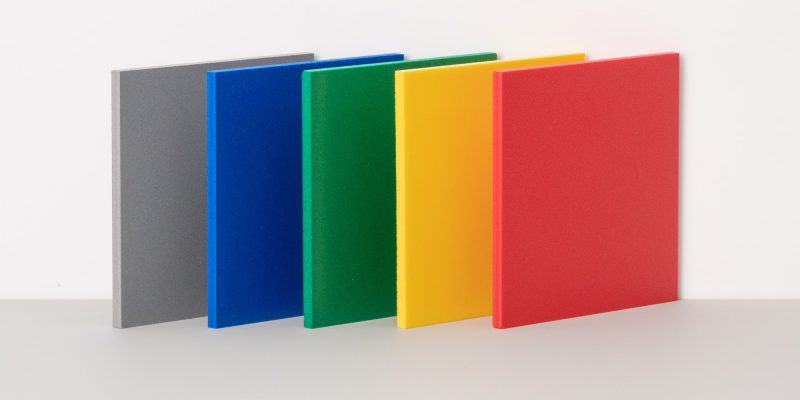

Introducing Foamex

Foamex, on the other hand, is a specific type of foam that stands out due to its dense and rigid nature. Also known as PVC foam board, Foamex is manufactured using a unique process that involves expanding polyvinyl chloride (PVC) through a combination of heat and pressure. The resulting material is rigid, durable, and resistant to moisture, making it well-suited for outdoor signage, exhibition displays, and construction applications.

Density and Rigidity

One of the key distinctions between foam and Foamex lies in their density and rigidity. Foam is characterized by its lightweight and soft nature, offering cushioning and flexibility. In contrast, Foamex boasts a higher density and rigidity, making it more suitable for applications requiring structural integrity and stability. If you’re in need of a material that can withstand heavy loads or provide a sturdy surface, Foamex is the ideal choice.

Versatility and Customization

Foam and Foamex both offer versatile options for customization. Foam can be easily moulded into different shapes and sizes, allowing for intricate designs and tailored solutions. It can also be cut or shaped to accommodate specific requirements. Foamex, on the other hand, offers greater dimensional stability and can be fabricated into larger panels or sheets without compromising its structural integrity. This makes Foamex an excellent choice for large-scale signage and displays.

Outdoor Applications

When it comes to outdoor applications, Foamex takes the lead due to its superior weather resistance. Thanks to its closed-cell structure, Foamex is less prone to moisture absorption, ensuring long-term durability even in challenging outdoor environments. It can withstand exposure to sunlight, rain, and temperature variations without warping or deteriorating. Foam, although versatile, is more susceptible to moisture and is best suited for indoor applications.

In conclusion, foam and Foamex may share some similarities in terms of composition, but their properties and applications differ significantly. Foam’s lightweight and cushioning properties make it ideal for packaging and upholstery, while Foamex’s density, rigidity, and weather resistance make it a top choice for outdoor signage and displays. By understanding these distinctions, you can confidently select the right material for your specific project, ensuring optimal performance and longevity. So, whether you’re packaging delicate items or planning an eye-catching outdoor display, consider the unique qualities of foam and Foamex to make an informed decision.